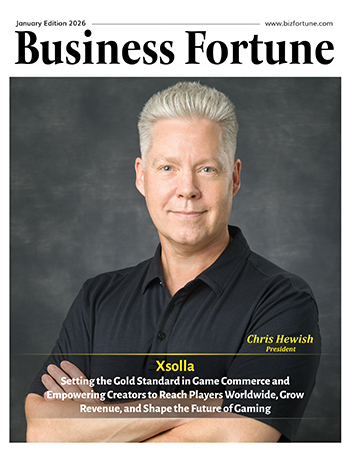

- Xiaoming Li

In fulfillment centers that manage non-sortable inventory, storage design is not just about where items are placed. It shapes how labor is organized, how capital is spent, and how a facility performs over time. Choosing the right system is a long-term decision that affects cost, capacity, and operational efficiency.

This article compares two vertical storage systems commonly used in large-scale fulfillment centers: pallet racking and pallet shelving. Based on engineering models and operational data from Brazil, India, and the United States, the comparison covers storage density, startup investment, labor impact, and total financial performance over a ten-year horizon.

Two Systems with Distinct Designs

Pallet racking and pallet shelving serve the same core function, but their designs and workflows differ significantly.

Pallet racking uses a single-level layout with wide aisles. It depends on powered industrial trucks, or PITs, for both vertical and horizontal movement. This design is widely used, straightforward to install, and easy to modify when operational needs change.

Pallet shelving adds multiple levels, typically one ground floor and three elevated decks. Aisles are narrower, and movement is divided into two types. Workers move horizontally using pallet jacks and picking carts, while vertical reciprocating conveyors, or VRCs, handle vertical movement. This approach increases storage density but adds to infrastructure and coordination requirements.

Storage Density and Space Utilization

Pallet shelving provides a significant gain in storage density. In the study based on the Brazil site, shelving achieved the same storage volume as racking while using only 47 percent of the floor area. That amounts to a 176 percent increase in density compared to racking.

This improved density leads directly to lower lease costs. Because less space is needed to store the same amount of inventory, total leasing costs for a shelving-equipped site were less than half those for a racking-equipped site.

However, reducing the size of the footprint does not automatically result in a more affordable or efficient system. The full cost picture includes the capital needed for construction and startup, which varies significantly between the two systems.

Construction Requirements and Initial Investment

.webp)

Shelving systems require a more complex and costly buildout. Multiple levels must be structurally supported. Fire protection systems, lighting, and ventilation must be added to each deck. VRCs need solid foundations, and safety systems must be installed across the elevated levels.

These requirements increased the construction costs for shelving by 17 percent compared to racking.

Startup costs showed even more contrast. Shelving required approximately 5.8 million dollars in startup capital. Racking needed only 2.4 million. The cost difference came from the purchase and installation of shelving platforms, vertical lift equipment, fire safety systems, and supporting infrastructure. Racking concentrated costs on PITs, cage carts, and staff training.

For sites with limited budgets or tight construction timelines, this large capital gap may be a major constraint.

Labor Efficiency and Workforce Structure

Each system changes how labor is deployed within the warehouse.

Racking had better performance in pallet stow tasks. PITs enabled fast, direct movement both vertically and across the warehouse floor. Workers could place pallets quickly and efficiently.

Shelving performed better in picking. The compact layout and higher number of bins allowed workers to complete more picks with fewer steps. Although shelving added some support labor to manage vertical transfers, the total number of labor hours was still lower.

Shelving also reduced dependence on PIT-certified workers. These roles typically come with higher wages and can be difficult to staff in certain markets.

In the modeled scenario, annual labor costs for shelving were 242,801 dollars. Racking required 307,334 dollars for the same labor functions. This represented a 21 percent reduction in labor expenditure for shelving. In markets with rising labor costs or shortages of certified PIT operators, this labor savings can have a meaningful financial impact.

Financial Performance Over Time

The analysis modeled the full cost structure of each system across a ten-year period. It included lease, construction, startup, labor, and maintenance expenses. Although shelving offered long-term savings on lease and labor, its higher initial investment delayed breakeven.

With a 7 percent discount rate applied, shelving remained more expensive than racking through the tenth year.

This result suggests that shelving is not suitable for sites that expect to operate for fewer than 10 years. Projects with return-on-investment requirements in the five to seven-year range are unlikely to benefit from the efficiencies of shelving unless the capital investment is heavily subsidized or amortized differently.

Matching Systems to Site Requirements

Both storage models have valid use cases. The best choice depends on several factors, including budget, workforce capabilities, available floor space, and the expected operating lifespan of the facility.

.webp)

Pallet racking is the better choice when:

-

The project is short-term or transitional

-

Capital is limited in the early phases

-

The layout may need to change after deployment

-

The workforce already includes PIT-certified operators

Racking offers faster deployment, lower startup costs, and easier reconfiguration. It works well in facilities where speed, flexibility, or budget constraints are a top priority.

Pallet shelving is the preferred option when:

-

The site has a planned operational lifespan of ten years or longer

-

Land is expensive, and available floor space is limited

-

Labor costs are high, or certified PIT labor is challenging to hire

-

Maximizing storage capacity is essential to the business case

Shelving requires more capital but improves space efficiency and lowers long-term operating costs. These advantages only provide value when the facility operates long enough to recover the upfront investment.

Final Considerations for Decision-Makers

Storage system design influences much more than layout. It determines how labor is structured, how throughput is managed, and how capital is spent. These decisions carry long-term implications and should be evaluated carefully.

Pallet shelving provides clear gains in density and reduces labor costs over time. But those benefits only pay off when paired with the capital and operational timeline to support the investment. Pallet racking is less space-efficient but offers lower startup costs and greater ease of adaptation.

Facilities should model both systems using their actual throughput projections, floor plans, and budget scenarios. The right system will support the site's business goals while staying within financial and operational constraints.

About the Author

Xiaoming Li is a material handling and storage systems engineering specialist with a focus on fulfillment center design and operational strategy. With experience spanning North America, South America, and Asia, Xiaoming brings a data-driven approach to solving complex storage and labor challenges in large-scale distribution environments.