Home Industry Environmental Sustainability Turning Waste into Wealth: Tra...

Turning Waste into Wealth: Transforming Swine Lagoon Sludge into Renewable Resources

Environmental Sustainability

Business Fortune

20 January, 2026

-Aakanksha Harsh

Few issues in contemporary agriculture need as much innovation as the process of handling the hundreds of billions of tons of organic byproducts generated annually, from farms that raise livestock to crops that are processed. These byproducts of production contain vast untapped potential—yet that potential is realized only with the right engineering mindset.

Around the world, process engineers and scientists are reinventing the means of closing the loop between waste and resource, designing systems that not only reduce emissions but also build economic value for farms and for industries. The impetus for such transformation is a new generation of innovators who bring academic rigor in combination with practical experience.

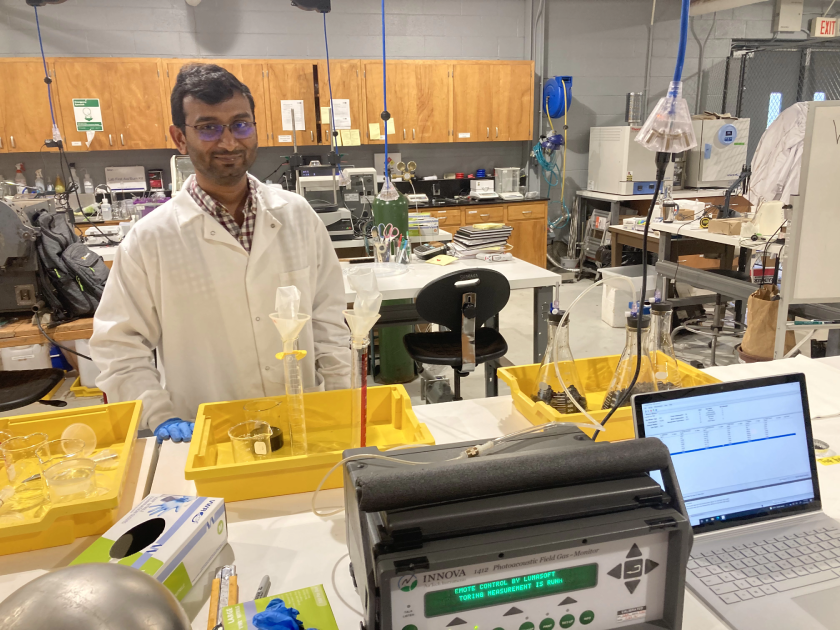

Senior Process Engineer Piyush Patil is one of many innovators whose work combines environmental stewardship with technological advancements in the agriculture-based bioenergy industry.

In reference to the process of converting waste into something of value, Piyush says: "Caring is what motivates me. The next time you pass a farm and it's 95 degrees outside and you smell that stench of lagoon sludge or manure that seems so troublesome--now that is a lot more valuable than what people thought and discarded.’’

He further reflects: ‘’This reminds me that innovating doesn’t have to be about being somewhere new from nothing--it evolves from putting value where it was hidden. When we transform something of no value into something useful--practical and humane, that's when we're engineering."

This has been the beacon for his travels from the farming community of India to large renewable energy projects throughout the United States. His career is a testament to how applied engineering, under genuine concern for the community of its providers, can create the potential for sustainability to be both a science and a common social cause.

Piyush, through research and practice-based solutions, represents a different type of engineer who demonstrates that the many facets of environmental integrity and economic development can be complementary, rather than competing.

New Visions for Farm Waste: Liability or Asset?

In rural Bhusawal, Maharashtra, Piyush grew up in the cycles of cropping—planting, harvesting, and the constant question of what to do with the scraps left behind.

He recalls: “My father and I used to talk about every crop cycle, all the crop residue and the manure wasted once the crop was harvested. Even as a kid, I would ask myself if that waste could become something useful as opposed to being a liability." That inquisitive spirit developed into a genuine professional pursuit.

Having received his bachelor’s degree in Chemical Engineering from the Vishwakarma Institute of Technology (Savitribai Phule Pune University), Piyush undertook research that considers environmental sustainability in conjunction with engineering design.

He made his way to North Carolina State University to earn a Ph.D. in Agricultural and Biological Engineering, with a particular focus on Sustainable Agricultural Waste Management.

Fieldwork was central to his doctoral journey—Piyush’s commitment to a data-centric philosophy took shape as he mentored undergraduates in the Pigs, Poultry, Planet, and Data-Driven Problem Solving (P4) program.

Through hands-on activities like swine lagoon sampling, model calibration, and data analysis, he emphasized that true precision arises as much from intellectual discipline as from advanced tools. Rather than handing out solutions, Patil posed thought-provoking questions, empowering students to discover insights independently.

It is within that program that Piyush developed his dissertation, "Evaluation of Valorization Pathways for Swine Lagoon Sludge Management in North Carolina," which addressed one of the state's most long-standing environmental issues: the accumulation of nutrient-rich sludge in swine manure lagoons.

He says: “Those experiences taught me to think like both an engineer and a farmer. I wanted to understand how systems fail in practice and how we could redesign them to ensure farmers enjoy the solutions. Every clogged line or lagoon overflow was a data point—a story of design not matching reality. Once you start reading those stories through data, you realize engineering is really about empathy expressed in numbers.”

Piyush’s research combined experimental data, response-surface modeling, and techno-economic analysis to develop practical waste-to-value systems. He published peer-reviewed papers on the effects of sonication on biomethane yield, nutrient recovery through composting, and the comparative lifecycle impacts of sludge treatment methods.

Piyush explains: “Studying waste management taught me that the key is energy recovery and integrating economics, emissions, and usability into one model. You need to know what the impact will be on the other side before optimizing one.’’

He further says: ‘’Getting more energy out of the system but doubling the emissions isn't progress—it's a disproportional reduction. What we really aim for is harmony between performance, cost, and environmental outcome, because only then can a technology earn its place in the real world.”

This body of early research has already proven significant in the field—its data-driven methods for sludge valorization now inform how agricultural engineers worldwide approach nutrient recovery and bioenergy generation.

Engineering Breakthroughs in Sludge Valorization

Piyush framed his own evolution from research in academia to practical innovation by converting scientific knowledge into solutions suitable for deployment in the field.

At North Carolina State University, he saw an essential need in the way that farmers handled the nutrient-laden sludge that was gathering at the bottom of swine lagoons. Conventional dryers were unreliable, consumed immense energy, and were cost-prohibitive.

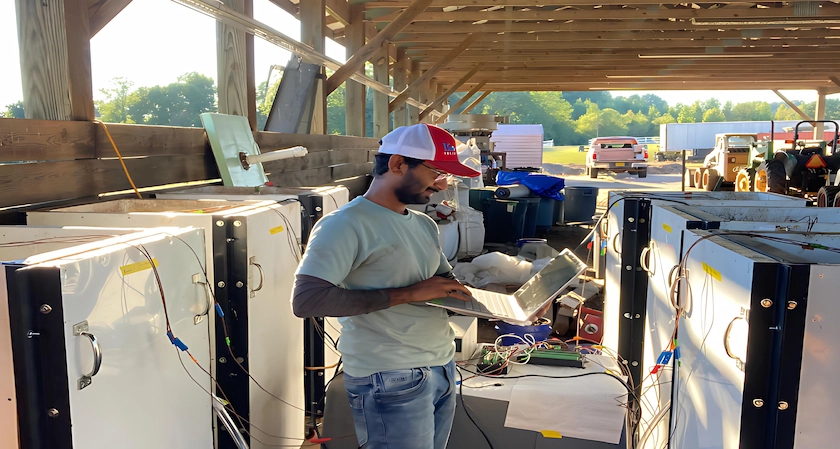

Piyush designed a solar-assisted greenhouse drying system, studied it on the farm, and developed automation logics to maximize drying performance given weather conditions, resulting in an affordable solution, energy efficient,t and performed well. A system that transformed how they could process sludge year-round.

Solar-Assisted Drying Systems

The greenhouse-based system integrated solar radiation, ambient temperature, humidity, and sludge-specific characteristics to create accurate predictions of moisture loss and optimize energy use.

Piyush explains: “Data has to lead design decisions. If a system doesn’t respond to environmental inputs flexibly, it’s just guessing. The goal is to make something that can adapt itself to conditions in real time.”

His design improved drying efficiency by over 30 percent compared to traditional methods, resulting in a reduction of energy and operator time by half. Those results, in turn, were reported in Environmental Technology & Innovation in 2025, illustrating that data-driven changes (incremental by nature) have benefits for environmental and operational costs.

But once buzz about the results circulated among waste management professionals in select states in the United States, there was potential for change in sludge-drying technology and newly recognized standards for a cost-effective option.

Dr. Mahmoud Sharara, Associate Professor and Extension Specialist at North Carolina State University, underscores the significance of that contribution: “Piyush’s research introduced a level of precision rarely seen in waste-handling models. He managed to combine field data, statistical modeling, and process design into a single framework that operators can actually use. His work has bridged the gap between academic theory and the day-to-day needs of agricultural producers.”

Composting & Lifecycle Optimization

The second of Piyush’s primary focuses was using the sludge to create nutrient-rich compost rather than waste.

He created composting mixtures that took into account the ratio balance between carbon and nitrogen as a means of promoting decomposition while conserving nutrients and minimizing the emission of greenhouse gases without degrading the soil.

Piyush shares: "It was determined that by monitoring precisely the ratio of feed to aeration, loss of methane and nitrous oxide was reduced while ensuring the end product contained phosphorus and zinc.’’ The results were published in the Journal of Environmental Management (2023) and have been used to inform composting practices in agricultural extension programs.

As a scalability indicator, Piyush carried out a rigorous techno-economic and lifecycle evaluation of three sludge valorization paths: composting, solar drying, and direct land application. Solar drying, followed by direct land application, was determined by him to create the smallest environmental footprint with the greatest return on investment.

He says: “It’s never enough to prove a process works technically. You have to prove it makes sense in economic and environmental terms—otherwise it won’t survive outside the lab. Engineering isn’t finished when the experiment succeeds—it’s finished when the farmer or operator can afford to keep it running. Sustainability that can’t sustain itself financially isn’t sustainability at all; it’s a pilot waiting to fail.”

His findings provided decision-making frameworks that are now used by both policymakers and private developers when assessing sustainable waste infrastructure. Piyush’s comparative modeling set a new benchmark for integrating economic and environmental performance in sludge management.

Together, these innovations exemplify how Piyush’s work has had a broader impact and influence in the industry, transforming waste treatment research into standardized, field-deployable tools that enhance efficiency, profitability, and environmental outcomes across the agricultural sector.

From Research to Scalable Systems

When Piyush joined Roeslein & Associates, he brought with him not only a doctoral foundation in waste valorization but also a philosophy that innovation must survive contact with reality.

His key question—how data-driven insights become repeatable—has, in turn, defined his industrial leadership.

At Roeslein, Piyush oversees the engineering workstreams dedicated to transforming livestock and food-processing waste into renewable natural gas (RNG). His transition from research to large-scale deployment involved translating predictive modeling into live operational control.

He explains: “In research, you have time to test variables one by one. In the industry, every variable changes at once. The challenge is finding where systems lose value and correcting it before the loss compounds. That’s where data tells its real story.”

His first significant milestone came with the optimization of three anaerobic digestion clusters serving multiple US farms.

By standardizing monitoring protocols and retraining operators, his team identified inefficiencies that, once corrected, increased biogas yields and boosted one client's annual revenue by 50%.

The project illustrated an example of how his work is already of significant significance in the field, proving that performance analytics can double output without new infrastructure or extra feedstock.

Prince Dugba, Ph.D., MBA, PE, Director of Science and Technology at Monarch Bioenergy, highlights the broader industrial implications: “Piyush’s technical leadership has been pivotal in helping Monarch reach its carbon-negative RNG goals. He applied his expertise in nutrient management and digester modeling to design siting strategies and Section 48 tax-credit compliance plans that accelerated more than forty farm projects across the Southeast.’’

He further reveals: ‘’His frameworks for real-time performance monitoring have become the backbone of our continuous improvement program, which has led to an increase in gas output and a reduction in emissions.”

Beyond revenue optimization, Piyush’s analytical rigor has shaped regulatory and environmental strategy.

His lifecycle and techno-economic assessment skills—first honed during his PhD program —now underpin Roeslein’s national interest projects. He signed on to a petition directed at the US Environmental Protection Agency in favor of including cover-crop biomass in the Renewable Fuel Standard. It is expected to bring new revenue streams to Midwestern producers while also reducing nutrient runoff.

Eric Bancks, Roeslein Renewables Division Vice President, notes the key importance of that cross-discipline knowledge: “Piyush leads engineering initiatives that sit at the intersection of biology, policy, and process design. The analysis across nine swine-to-RNG clusters has yielded double-digit performance gains, and his contributions to our EPA cover-crop and federal tax credit programs provide essential information for our capital planning. His ability to connect field data to national-level decision-making has produced measurable financial and environmental returns.”

Piyush’s current innovations extend further into product development. He is leading prototype testing for an improved hydrogen sulfide removal system and an anti-scaling solution for digester pipelines—both aimed at reducing downtime and maintenance costs.

He says: “Every recurring issue is an opportunity to engineer a permanent fix. If a design flaw costs operators a day, we can redesign it to save them a week. Every repetition of failure carries data—it shows you exactly where the weak points live. If you treat breakdowns as diagnostic signals, not setbacks, systems start teaching you how to improve them.”

These technologies illustrate how Piyush has made a significant contribution and difference in his industry—transferring anaerobic digestion applications from custom-made pilot systems to data-informed, scalable assets that drive profitability while achieving US climate and rural development objectives.

Through all of these, his unique combination of analytical insight and practical experience elevates waste-to-value engineering from a conceptual idea to a fundamental understanding.

Mentorship and the Next Generation of Engineers

For Piyush, cultivating a collaborative culture has been as important as the engineering itself.

In the long term, he believes collaboration is the key to mentorship, along with innovation, where every single step of your waste-to-value technology not only makes progress forward but also strengthens the people and the systems that support it.

At Roeslein & Associates, Piyush oversees teams of process, mechanical and agricultural engineers across multiple disciplines who design and improve renewable natural gas (RNG). His management style combines structure with autonomy, allowing each engineer to understand not only what they are building, but also why.

He says: “I’ve learned that precision is as much a mindset as it is a metric. When people understand the impact of what they’re designing—on emissions, on farmers, on soil health—they begin to treat every calculation like it matters. Precision isn’t about perfection—it’s about care. Once you teach that, quality becomes automatic because people feel accountable for the outcomes, not just the equations.”

That mindset can be dated back to North Carolina State University doctoral days, when Piyush tutored undergraduates in the Pigs, Poultry, Planet, and Data-Driven Problem Solving (P4) program.

He walked students through field sampling, analyzing compost, and digester performance evaluations—all to tie in theory with real-world results. Several of those students now work for bioenergy and environmental engineering companies, reflecting the practical systems-thinking mindset he began instilling from the early stages.

Christopher Hopkins, a research associate with the Department of Biological and Agricultural Engineering, North Carolina State University, fondly recalled how the ethos inspired his work out there: "Piyush is one of the most intrinsically motivated engineers I have ever had the pleasure to work with. From taking samples from the hog-waste lagoon, to checking data models for flaws, he approached the work with creativity, enthusiasm, and a refreshing degree of immersion.’’

He further says: ‘’I’ve seen him improvise fixes in real time—once, when our pump jammed during sampling, he solved it using the simplest tool at hand. That adaptability and teamwork set the tone for everyone around him.”

Within Roeslein, Piyush applies the same principle of guided autonomy. He organizes weekly technical debriefs where junior engineers present performance data and propose improvements, encouraging evidence-based debate.

Piyush reflects: “Mentorship isn’t about giving answers. It’s about teaching people how to question their own assumptions and validate their logic through data. The best engineers I’ve worked with don’t need instructions—they need good questions. When you develop that habit, you're not just teaching students how to solve problems; you are teaching them how to think critically in every context."

Another aspect of Piyush's professional activity, which also reflects his influence beyond his committed work within the industry, is his involvement with the general engineering community.

He is an active member of the American Society of Agricultural and Biological Engineers and the American Association for the Advancement of Science (AAAS), where he contributes his skills and expertise to technical committees addressing issues related to waste valorization and renewable energy policy.

His scholarship has been presented to the ASABE Annual International Meetings, by which Piyush was also awarded first place at the ASABE Bioprocess Start-up Competition in 2022.

He is also part of the Waste to Worth Symposium, bridging gaps between research and scholarship work and their implementation in the industry.

Piyush's mentoring system, based on honesty, inquiry, and shared accountability, demonstrates the educational impact of his work in this field, changing the way young engineers think about problems in bioenergy.

In highlighting accuracy as a collaborative process, rather than an individual feat, Piyush has himself been central in redefining professional culture among groups of agricultural engineers. It is, in this process, not only cleaner technologies that he is cultivating but also collaborative mindsets that are critical for sustainability.

Engineering Value Where Others See Waste

At every juncture of life, Piyush has demonstrated that sustainability is about more than abstract conceptualization: it is a design discipline.

Each action or decision he is obligated to take, either in laboratory modeling or based on implementation of large-systems, affects people and the planet. His efforts are transforming the concept of waste from something that needs to be contained and disposed of into a productive and valuable resource that can restore local economies and contribute to global decarbonization.

Piyush reflects: “Every system we optimize should make sustainability practical. That means creating solutions that are self-sustaining in technical, economic, and environmental aspects. When a process starts generating value across all three, it becomes a self-sustaining system."

This conviction drives his work at Roeslein & Associates, where performance models, prototype biochars, and nutrient-recovery systems turn academic knowledge into practical advantages for both industry and farmer.

Every innovation highlights a guiding principle of his own career: engineers can address complex environmental problems when they combine meticulous technique with a profound sense of the end user's requirements.

Piyush views the next decade of waste-to-value development as a shared opportunity rather than an individual mission.

He says: “Progress depends on how well we connect ideas across disciplines and borders. If we treat waste conversion as a collaborative ecosystem—where data scientists, farmers, and engineers all contribute—we’ll speed up both climate goals and rural prosperity.”

Today, several U.S. waste-to-value pilot programs reference Piyush’s frameworks as best-practice models. By striking a balance between precision and purpose, Piyush has set a new benchmark for the practice of agricultural engineering within the circular economy. His work stands as a testament to the potential for technological knowledge, when rooted in genuine need, to become a lasting influence that extends beyond personal projects or technologies.

About the Author: Aakanksha Harsh is a business and technology writer focusing on digital transformation, startups, and emerging trends.