Home Innovation Robotics Comau equips HYCET with a high...

Comau equips HYCET with a high-volume, automated assembly line

Robotics

Business Fortune

01 Febuary, 2024

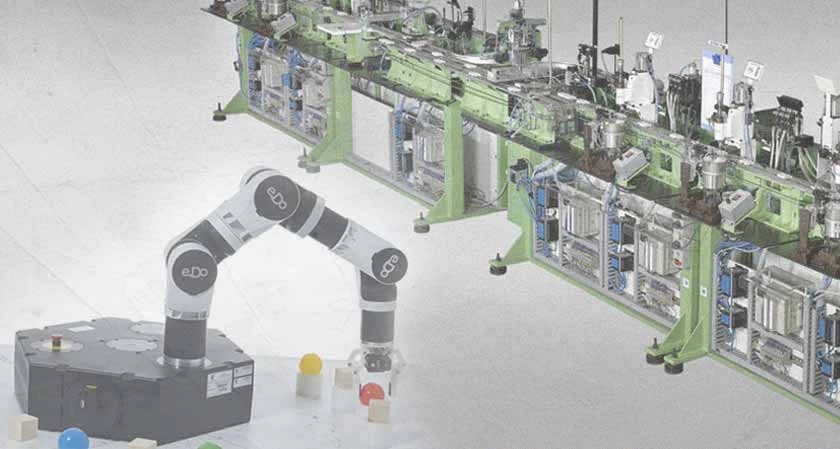

For HYCET, a wholly-owned subsidiary of Great Wall Motor and a top producer of DHT (Dedicated Hybrid Transmission) technology, Comau designed and implemented a high-volume, automated assembly line.

A next-generation transmission system called the L.E.M.O.N. hybrid DHT makes it possible to operate electric motors and gasoline engines simultaneously, facilitating effective power sharing between them.

With an annual production capacity of 150,000 units per line and a cycle time of less than two minutes, Comau's end-to-end solution uses a total of 12 robots spread across six lines to meet the customer's large-scale manufacturing targets.

Within the parameters of the project, Comau has created all required parts, including assembly test lines, e-motor assembly lines, gear and shaft assembly lines, and main assembly lines.

Crucial processes in the system enable full-process assembly from separate components to fully operational units.

In fact, the production line designed by Comau is highly adaptable to various market demands.

Additionally, Comau has employed a process-integrated overall station design to ensure 90% equipment availability and stability throughout the production line.

The line's scheduling and management can be optimized by HYCET with the use of a Manufacturing Execution System (MES). In order to maintain quality control throughout the whole manufacturing process and facilitate data traceability in the future, important process parameters like force and displacement are also continuously monitored.

Vice President of HYCET Technology Co. Wu Hongchao states: "Great Wall Motor's DHT system performs exceptionally well thanks to HYCET's DHT technology, which represents cutting-edge innovation in the hybrid vehicle sector."