Business Fortune

One of the most significant aspects in terms of logistics and supply chain management is flexibility with which businesses can try adapting themselves to fluctuating demands, several unforeseen disruptions as well as the dynamics of international trade across the world. Flexe is one shining example having its establishment date as 2013 and headquarters based in Seattle, offering tech-empowered flexible warehousing infrastructure in the logistics sector.

Tech-Based Solutions for Changing Supply Chains

With an extremely robust Flexe platform, it is seamlessly administered in a truly integrated manner with the prevailing operations of a business, meaning that 700 warehouse operators across the United States and Canada can be accessed and adopted by an operational nexus, in view of that it can be considered with or without capital expenses or extensive contracts as part of system costs. Companies faced with shifts in stock, production problems, or large periods of their annual sales cycle have the perfect answer of using the flexible warehousing infrastructure at Flexe.

Flexe provides companies a critical covetous point: it allows them to adapt fast in line with surge and dips in demand. The invention of codable pallets for storing excessive stuff through bulk buy, sudden cuts on production, or perhaps seasonal sales; the whole system of Flexe could scale down or up based on demand of operations at the moment. This way, we get more adaptive supply chains capable of being scrambled without coming down, thereby saving up on either efficiency or performance.

Prepare for the Unexpected

During times of world economic uncertainties, natural disasters and a changing consumer behavior, supply chain risks are necessary to manage. The concept of Flexe offers a promising solution as businesses can buy the flexibility of having a stock and rent the flexibility of a physical warehouse space. The benefits of the company and the least impact of unforeseen events are provided by this approach. In addition, dynamic changes of warehousing space enable risk of stock outs and lost sales. Flexe allows businesses to grow operations quickly and without long term commitments and heavy capital costs in times of peak seasons or economic downturns, giving a quick response to fluctuate from demand and supply chain disruption.

Optimizing Supply Chains toward Efficiency and Growth

Scalable to accommodate a vast network of warehouse operators, Flexe allows a company to optimize its supply chain. The incorporation of order, inventory, and warehouse management would make work streamlined. Offering centralized functionality and real-time visibility into the performance of supply chain workers ensures that Flexe has elevated the level of efficiency for users. The company executes data-driven strategies that track performance continuously on the ground and apply the knowledge gained from the market to store replenishment SLAs and quicker product launches. A logistic analyst guides operational processes to ensure balance, effectiveness, and efficiency of the supply chain.

The Unmatched Flexe Value: CapEx-Free, Complexity-Free

The Flexe proposition is strong: no upfront capital expenditure and no complexity associated with traditional warehouse management. In fact, Flexe offers flexible, transactional pricing, which allows a company to build their supply chain without fixed costs, allowing for an improved ROI through reduced warehousing and transportation expenses. Flexe will help companies reach new markets, optimize networks, or test sales channels, with enhanced speed of delivery, as well as have lower transportation costs-important factors in keeping pace with the competition in eCommerce and Omni channel retailing.

Incorporating the Flexe factor with Scale Technology

Flexe enables rapid and straightforward integration with existing systems. In a single instance, businesses can be operational in weeks, rather than months, using a one-to-many interface model, which eliminates the need for complex setup processes and simplifies the management of the distribution, fulfillment orders, availability, and operation across an extensive network of warehouse providers.

Data analytics and reporting capabilities offer insight into inventory performance while pushing orders in real time. Flexe offers businesses an opportunity to focus on growth by taking the logistics complexity out of the operational process, improving their strategic operational efficiency.

Customer-Centric Spectrum

Always a customer success company, Flexe connects businesses to a dedicated logistics analyst so they know exactly what to expect for delivery consistency and operational excellence over the entire network. Flexe is able to service at a high level while maintaining scalability and flexibility through offering individualized services. Flexe has an extensive list of satisfied customers — few of them Fortune 500 — that shows just how its innovative approach to warehousing is a strategic differentiator. The goal is to convince the traditional warehousing infrastructure that adaptability is a must for navigating an uncertain and rapid marketplace.

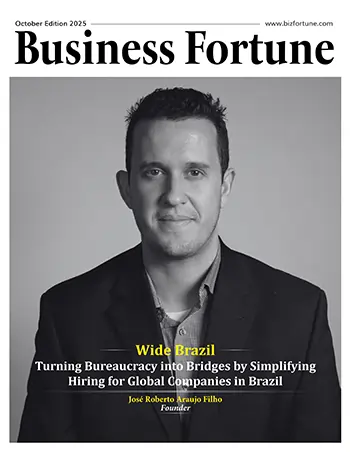

About the Leader

Karl Siebrecht, Co-founder & Chief Executive Officer of Flexe, is a seasoned technology executive, with leadership experience in both startups and large, global corporations. Prior to co-founding Flexe, Karl was CEO of AdReady, a Seattle-based advertising technology company. He is also a founding Board member of EnergySavvy, a SaaS-based solution for energy efficiency management. Previously, Karl was President of Atlas at aQuantive, before its $6B acquisition by Microsoft, and earlier in his career he was a Manager at Bain & Company in Boston and a Diving Officer in the U.S. Navy.